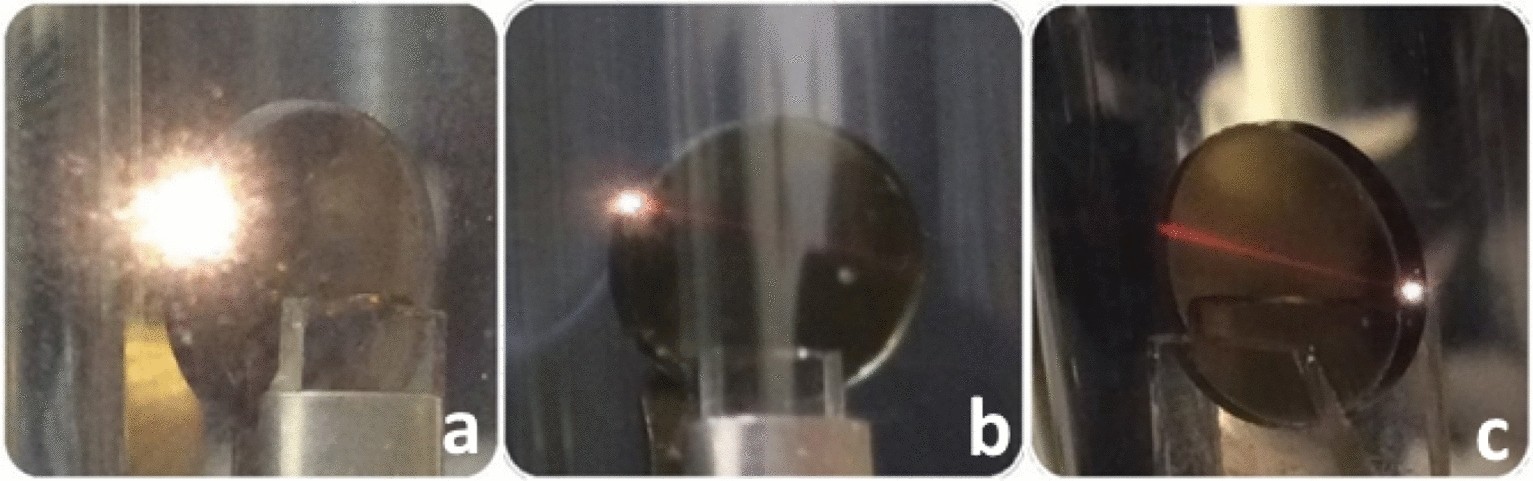

In this work we report the white light emission in transparent Cr:YAG ceramic pellet upon irradiation with focused beam of CW infrared laser diode. It was found that this phenomenon is specifically related to interaction of laser beam with a surface of the pellet. The white light was emitted outside an irradiated spot at the surface of the pellet and did not penetrate inside the pellet. Moreover, the red emission related to two-photon absorption along the laser beam penetrating the Cr3+:YAG pellet was observed. Interaction of the laser beam with the surface of the pellet leads to an efficient white light emission from an outer side of the pellet. The resulting white light emission did not entry back the pellet. Multiphoton ionization leading to intervalence charge transfer followed by light emission was proposed as the mechanism of experimentally observed white light emission.

Introduction

Laser induced white emission (LIWE) in rare earth doped oxides excited by focused laser beam in vacuum was reported by Wang and Tanner1. Since then, LIWE was observed in different materials placed in vacuum ambient2,3,4,5,6,7,8. An increase in the ambient pressure was accompanied by a decrease of LIWE intensity, which remained stable up to critical point9,10. The excitation power dependence of LIWE intensity demonstrated a threshold behavior for multiphoton avalanche processes1. Numerous models have been proposed for white light generation in lanthanide-based systems including the intervalence charge transfer (IVCT)9,11, multiphoton absorption12, thermal avalanche13 and others2,14.

Recently we have reported LIWE in transparent Cr:YAG ceramics15,16. In a course of studies we have found that an occurrence of white emission was closely related to the interaction of focused laser beam with the surface of ceramics. In the present study we study the LIWE process in Cr:YAG transparent ceramics under CW IR laser excitation. It was shown that LIWE is the surface related phenomenon and the light is emitted only out of the interaction spot of laser beam and does not penetrate the ceramics.

Experimental

The Cr4+:YAG ceramics was made in Institute for Single Crystals, Kharkiv, Ukraine. The Cr:YAG samples were sintered in vacuum furnace by solid state reaction. High purity High purity reagents: Al2O3 (purity > 99.99%, Baikowski, d = 0.15–0.3 μm), Y2O3 (purity > 99.999%, Alfa Aesar, d = < 10 μm), Cr2O3 (purity > 99.97%, Alfa Aesar, d = < 100 nm), CaO (purity > 99.999%, Sigma Aldrich, d = < 0.1 μm) were used as starting materials. Powders were taken in stoichiometric ratio, concentrations of Ca and Cr were taken in order to replace Y and Al, respectively. Cr2O3 and CaO powders were weighted precisely to obtain chromium and calcium content of 0.1 and 0.5 at.%, respectively9. Homogenization was performed by ball milling for 15 h using high purity Al2O3 balls. The milled slurry was dried for 1 day in air and sieved through a 200-mesh screen. The compacts were prepared by applying isostatic pressing at P = 250 MPa. Sintering was performed at 1750 °C for 50 h using solid state reaction (SSR) in vacuum furnace.

Scheme of the LIWE measurement setup is shown in the Fig. 1. The samples were placed in a vacuum cell connected to EXT75DX turbo molecular vacuum pump with TIC controller (Edwards) to achieve the pressure of 10–4 mbar. To collect the emission spectra, the AVS-USB2000 Avantes Spectrometer was used. Emission spectra were measured using an infrared continuous wave Nd:YAG laser 3,4 W as an excitation source. The spectra were not corrected to the detector sensitivity. In order to protect the CCD camera, FGS900S filter was used for measurement of the power dependence of LIWE intensity. LIWE was measured under P -10–4 Pa. The effect of pressure on the LIWE intensity of Cr:YAG ceramics was studied in our previous work15.